About Us

Meltology Induction Pvt Ltd is a most popular and reliable manufacturer for induction melting machines and induction heating machines. We are rapidly growing company with customer centric attitude.

- Rapidly growing orgnisation

- Highly motivated and commited team

- Best in Class products

We have high-tech manufacturing facilities including latest cutting edge technologies to produce world class products. We have highly motivated and technically qualified team for precise engineering and designing of our products. Our products are highly demanded due to their robust design, lowest maintenance and highest energy efficiencies. read more..

How Does Induction Technology Work..?

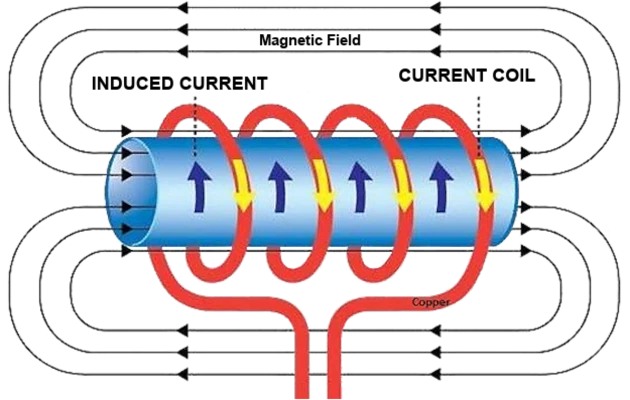

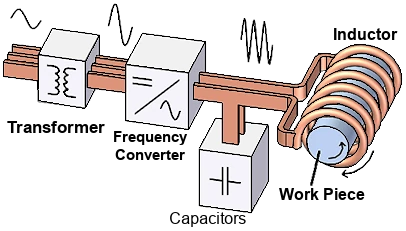

Magnetic field is created when electric current passes through a conductor coil. This magnetic field agitates the electrons in the work piece placed in the magnetic field. These agitated electrons produce heat in the work piece.

The reversal of magnetic field produced by AC supply heats the work piece. Based on the application purpose (heating or melting), the design of the inductor coil is prepared. The heating or melting work is done without conventional fire flames.

This way induction technology is clean and environment friendly technology.

German Technology, Indian Excellence

Our induction system utilizes microcontroller-based IGBT (Insulated Gate Bipolar Transistor) technology. It combines advanced German technology with Indian engineering and design, setting our systems apart from other induction heating and melting solutions.

The control process of our system follows the steps below:

Technical Advantages & Safety Features

- Advanced control system powered by a high-speed digital microcontroller

- Smooth start-up enabled by DC capacitors to minimize voltage surges

- 99% input power factor ensures maximum energy efficiency

- High-performance SEMIKRON IGBT modules for smooth and efficient operations

- Low harmonic distortion thanks to microprocessor-based control

- Multi-tripping indications available on both the control card and control panel

- Temperature monitoring via thermocouple for low-melting metals, and pyrometer control for high-melting point materials

- Optimized inverter design reduces switching errors and current loss

- Fiber-optic communication reduces electrical and eddy current interference

- In-house developed control card operates efficiently in standard cooling environments

- Regulator-based current controller for easy adjustment of limits from the control panel

- Wiring harness meets ISI standards and uses high-quality connectors

- Melting pot constructed with non-conductive materials, refractory base, and premium coil coats for durability (includes complimentary grout for re-insulation)

- Built-in interlock error detection ensures operational safety

- Reliable digital circuit design with low maintenance needs

- High-grade water-cooled film capacitors from Alcon for superior capacitance

- Panel displays water flow and failure alerts

- CF hoses enhance the lifespan of water-cooled copper connections, equipped with premium brass connectors

- SEMIKRON driver card ensures high reliability and global quality standards

Why to Choose Meltology Induction Pvt Ltd?